Understanding WMC SC-4002-6 Pulley Size for Optimized Mechanical Systems

The WMC SC-4002-6 pulley is a critical component used in various mechanical systems, designed to provide optimal load transmission, reduce friction, and ensure smooth operations. Pulley systems play a vital role in machinery and vehicle applications, from power transmission to hoisting mechanisms. Choosing the right pulley size is essential to maintain performance, durability, and efficiency. In this article, we will explore the significance of the WMC SC-4002-6 pulley, how to select the appropriate size, its mechanical advantages, and how it fits within various systems.

What Is a Pulley System?

A pulley is a simple machine comprising a wheel on an axle, with a rope, belt, or chain wrapped around it to transfer power and motion. The pulley system can change the direction of force and help lift or move heavy objects with reduced effort. In many industrial settings, pulleys are an indispensable part of belt-driven systems for power transmission.

The Role of Pulley Size

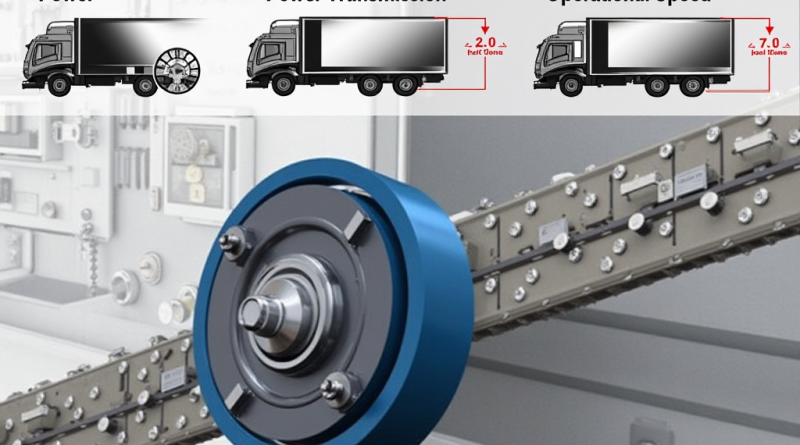

The size of a pulley, particularly in belt-driven systems, plays a crucial role in determining its mechanical advantage, torque, and speed. Pulley size affects how fast or slow the driven component moves relative to the driver component. Smaller pulleys rotate faster than larger pulleys if they are connected by the same belt or chain.

Importance of WMC SC-4002-6 Pulley Size

The WMC SC-4002-6 pulley is designed to meet specific requirements for mechanical systems in various industries. This pulley size is significant because it directly impacts the following:

- Efficiency of Power Transmission: The size determines how much power is transferred between the driver and driven parts.

- Operational Speed: Larger pulleys rotate slower, while smaller pulleys rotate faster, affecting the system’s operational speed.

- Torque and Force Distribution: The right pulley size ensures a balanced torque distribution, leading to smoother performance.

How to Choose the Right WMC SC-4002-6 Pulley Size

Choosing the appropriate pulley size depends on the specific requirements of the system. Here are some factors to consider:

- Load Requirements: Assess the load that needs to be lifted or moved. Larger loads typically require larger pulleys to distribute the force more evenly.

- Speed and Torque Specifications: If you need higher torque at lower speeds, opt for a larger pulley. Conversely, if you want higher speeds, a smaller pulley is preferable.

- Belt or Chain Type: The type of belt or chain used with the pulley should match the groove design and size of the pulley to ensure a tight and secure fit.

- System Configuration: Depending on whether you have a single pulley system or multiple pulleys in tandem, you will need to adjust the size for optimal performance.

Mechanical Advantages of the WMC SC-4002-6 Pulley

The mechanical advantage (MA) of a pulley system determines how much effort is reduced when lifting or moving a load. With the WMC SC-4002-6 pulley, you can expect:

- Load Reduction: Less force is required to lift or move objects compared to systems without pulleys.

- Improved Power Transfer: It ensures minimal energy loss during power transmission.

- Versatility in Applications: Its size makes it suitable for a range of mechanical systems, including conveyors, hoists, and belt-driven machines.

Applications of WMC SC-4002-6 Pulley Systems

The WMC SC-4002-6 pulley system can be used across various industries due to its adaptability. Here are some key applications:

- Manufacturing Plants: Pulleys are integral to conveyor belt systems used in assembly lines and manufacturing.

- Automotive Industry: In cars, pulleys are used in engine components like the timing belt and alternator, where precise control of power distribution is required.

- Elevator Systems: Pulleys allow elevators to lift and lower safely by distributing the weight across multiple wheels.

- Agriculture Equipment: In farm machinery, pulleys help operate equipment such as tractors, combines, and plows.

Factors Impacting Pulley Efficiency

While choosing the WMC SC-4002-6 pulley size, it’s crucial to ensure optimal efficiency by considering:

- Friction: Excessive friction between the pulley and belt can lead to energy loss.

- Belt Tension: Proper tension is necessary to prevent slippage or wear and tear on the pulley.

- Maintenance: Regular lubrication and inspection are essential to keep the pulley in good working condition.

Pulley Material: A Critical Factor

The WMC SC-4002-6 pulley is often made from durable materials such as steel or cast iron, designed to withstand heavy loads and high rotational speeds. The choice of material impacts its:

- Durability: Steel or cast iron pulleys are resistant to wear and tear, making them ideal for high-stress environments.

- Weight: Heavier materials can contribute to increased efficiency by providing stability.

- Corrosion Resistance: Pulleys in outdoor or harsh environments require rust-resistant coatings or materials to ensure longevity.

Conclusion

The WMC SC-4002-6 pulley size plays a vital role in optimizing the performance of mechanical systems across various industries. Selecting the right pulley size is essential for maintaining balance in speed, torque, and load management. It also helps ensure efficient power transmission, reduce operational effort, and prolong system life. With proper maintenance, attention to material quality, and an understanding of system requirements, this pulley can significantly improve operational performance.

Frequently Asked Questions (FAQs)

- What is the ideal pulley size for high-torque applications?

- For high-torque applications, larger pulleys are generally preferred as they help distribute force evenly and operate at lower speeds.

- How do I know if my pulley size is correct for my system?

- To determine the correct size, you need to consider factors such as load requirements, system speed, and torque specifications. Consulting a mechanical engineer or using online pulley calculators can help.

- What materials are commonly used for pulleys?

- Pulleys are commonly made from steel, cast iron, aluminum, and sometimes plastic, depending on the application and required durability.

- How often should pulleys be maintained or replaced?

- Pulleys should be inspected regularly for wear, corrosion, and proper belt tension. Replacement is typically required when there is significant wear or damage, usually every 3-5 years depending on usage.

- Can I use any belt with the WMC SC-4002-6 pulley?

- No, it is crucial to match the pulley’s groove size with the correct belt type to ensure a secure fit and efficient power transmission.

- What is the difference between a pulley and a sprocket?

- While both pulleys and sprockets are used for power transmission, pulleys typically use belts, and sprockets use chains. The choice between them depends on the application.

- Can pulley size affect fuel efficiency in vehicles?

- Yes, pulley size in vehicles (such as in the alternator or air conditioning system) can impact engine efficiency, which in turn affects fuel consumption.